ProModel®

Advanced Simulation and Predictive Analytics

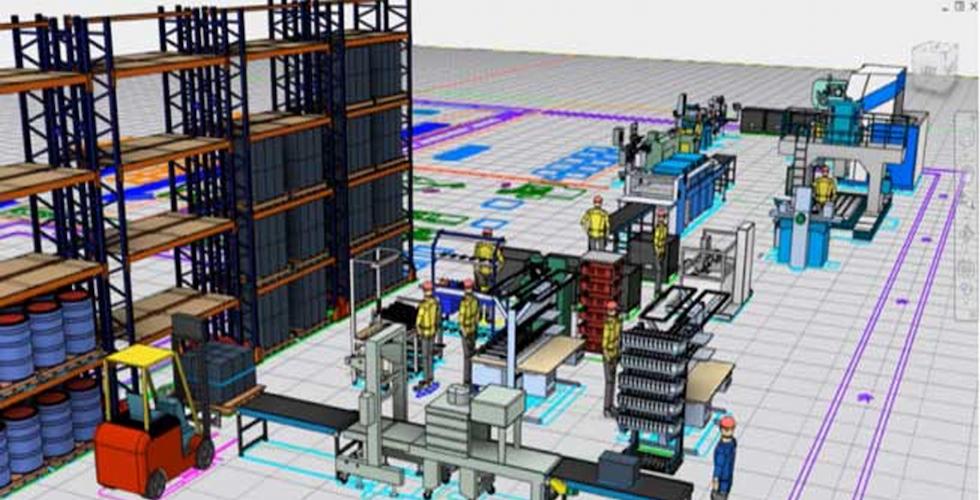

ProModel® is BigBear.ai’s simulation-based predictive analytics platform designed to help organizations optimize processes, reduce inefficiencies, and make data-driven decisions. By modeling real-world scenarios, ProModel® empowers industries such as manufacturing, warehouses, logistics, healthcare, and defense to predict and enhance operational outcomes.

Predict Process Behavior

Create detailed simulations of your systems with ProModel®. Accurately forecast how they will perform under any condition, and make confident, data-driven decisions.

Test Operational Responses

Use ProModel® to analyze countless scenarios. See how your systems react to changes, and find the perfect solutions to optimize performance and efficiency.

De-risk Change Impact

See the impact of any change to your environment before implementation. Use ProModel®‘s powerful simulation capabilities and data-driven metrics to ensure success and minimize risk.

Model Your Process

ProModel.ai provides an API to embed within your current operational systems and applications to harness the power of advanced discrete event simulation. Developers benefit from greater flexibility and customization compared to traditional solutions, ensuring seamless connections and improvements without disrupting existing workflows.

Simulate Outcomes

Model and simulate your processes to identify bottlenecks. Develop and test multiple scenarios, compare results via ProModel®’s Output Viewer with the latest Microsoft® WPF technology, or export to utilize in your own business intelligence tools.

Implement with Confidence

Review the impact of operational as well as strategic changes, risk free, with predictive scenario comparisons. Determine optimal business performance with a high probability of meeting your business goals.

The ProModel Advantage

Introducing ProModel.ai Digital Twin

BigBear.ai’s new ProModel.ai takes modeling and simulation a step further, connecting real-time operational data to create an always-updated digital twin using an API. This digital twin not only answers strategic questions but facilitates real-time operational decision-making.

Multi-Industry Impact

Manufacturing

Reduce downtime, identify bottlenecks, and improve efficiency with ProModel® — enabling smarter decisions and maximizing productivity before costly changes are made.

Logistics and Supply Chain

Optimize inventory, streamline workflows, and predict disruptions — ensuring smoother operations, reduced costs, and improved delivery performance.

Healthcare

Improve patient flow, reduce wait times, and enhance resource allocation — ensuring better efficiency, lower costs, and improved patient care.

Warehousing

Improve inventory management, streamline workflows, and maximize space utilization — reducing costs, increasing efficiency, and ensuring faster order fulfillment.

Transportation

Optimize the flow of traffic and goods, reduce delays, and improve resource allocation — ensuring faster, more reliable, and cost-effective operations.

Government & Defense

Lightweight by design, AI orchestration and contested logistics platforms enable faster-time-to-field of any AI model to the edge, even in low/no-bandwidth environments; and established connector and model libraries vastly expedite integration time.

Advance Your Modernization Efforts

with Simulation and Digital Twin

Talk to an expert to learn how BigBear.ai’s ProModel® technology

will help you optimize your operations.

News and Resources

Solution Brief

ProModel Solution Brief

News

Partner Story: AWS Simulation and Digital Twin to Increase Warehouse Productivity

Press Release

BigBear.ai and Spinnaker SCA partner to elevate offering in supply chain consulting, leveraging advanced simulation of complex operations

Press Release