Manufacturing

and Supply Chain

Delivering AI for effective operations across logistics, manufacturing, warehousing, and healthcare

Pivotal Capabilities for

Enterprise Modernization

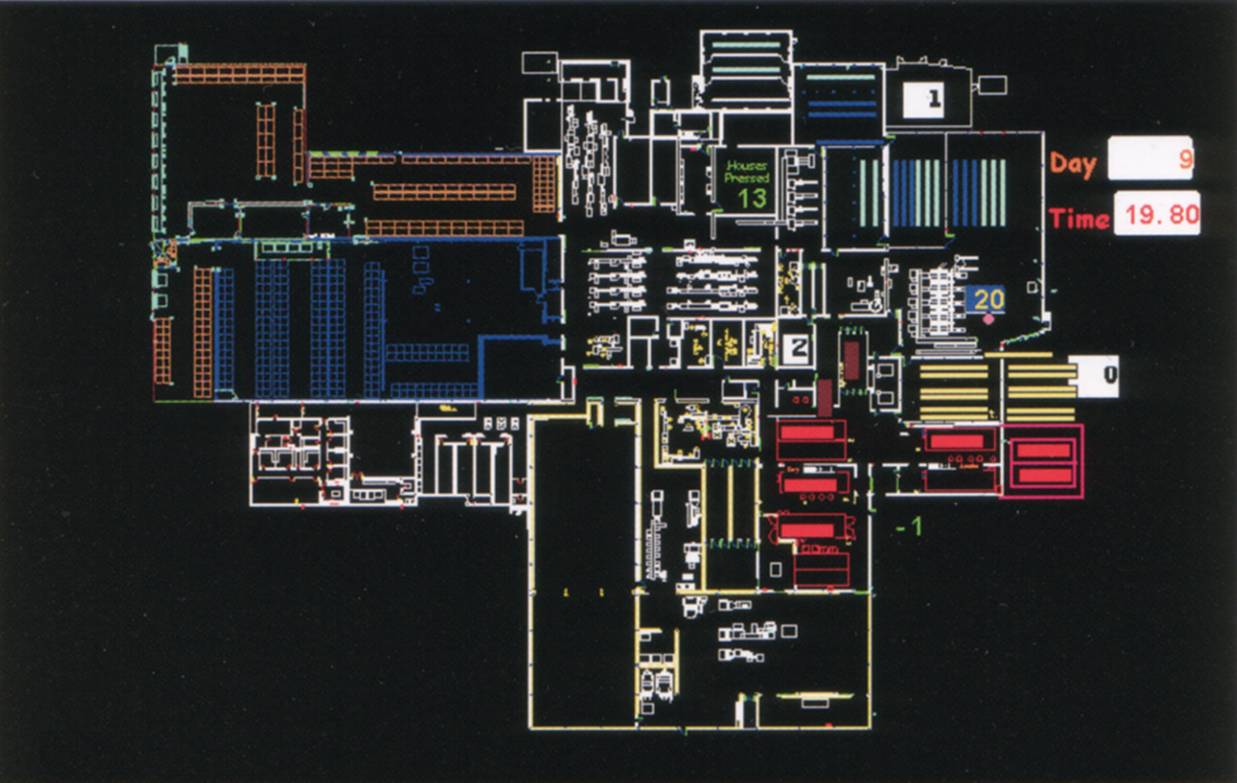

Digital Twin for Management of Live Operations

Create dynamic, real-time virtual replicas of physical assets, processes, and environments. Operators can monitor and simulate complex systems with unparalleled precision through AI-driven analytics and predictive modeling. With digital twin solutions, leaders in shipbuilding and manufacturing can now anticipate disruptions, streamline workflows, and make data-driven decisions to increase throughput and decrease downtime.

Stay ahead in an increasingly complex and competitive landscape with the ProModel® solution suite.

See how AWS has partnered with BigBear.ai to offer their customers Digital Twin solutions to increase warehouse productivity

Revolutionizing Shipbuilding and

Heavy Manufacturing

Transform operations with AI planning, from efficiencies in shipyards to manufacturing sites. By harnessing vast data streams, our solutions help manufacturers optimize production, reduce downtime, and enhance precision at every stage of the build process. BigBear.ai’s shipbuilding software platform can help drive efficiency, lower costs, and mitigate risks, while ensuring smarter decision-making and faster, more resilient operations.

Modeling and Simulation in

Project Planning

Validate and optimize investments before lifting a finger. BigBear.ai’s ProModel® suite allows decision makers to determine the impact on key objectives associated with changes to their operations.

Whether seeking to validate an existing proposal, or building project plans from scratch, our suite of Modeling and Simulation solutions allow organizations to simulate their unique environment with precision, and predict key outcomes with accuracy.

BigBear.ai and Spinnaker SCA partner to elevate offering in supply chain consulting, leveraging advanced simulation of complex operations

Empowering Healthcare Operations

BigBear.ai’s enterprise modeling and simulation platforms enable healthcare organizations to optimize scheduling, improve patient flow, and enhance resource allocation. Our AI-driven platforms help hospitals, pharmaceuticals, and medical suppliers anticipate demand, reduce bottlenecks, and streamline decision-making. By leveraging predictive analytics and discrete event simulation, FutureFlow Rx® enables data-driven strategies that can improve efficiency, reduce costs, and improve patient outcomes.

Biometrics for Facilities Security and Consumer Experiences

BigBear.ai’s facial recognition and biometric matching software, Trueface™, can be deployed on existing hardware for a myriad of commercial and enterprise applications. Improve your organization’s bottom line by providing AI-driven biometric solutions for identity verification, access management, and customer experiences at point-of-sale locations across various industries.

Point-of-Sale Payment Leader SoftPoint Selects BigBear.ai for Facial Recognition Matching Technology in Payment Transactions

Anticipate outcomes for confident decisions

Learn how to drive digital and physical operational efficiencies with confidence in predicting outcomes.